[ad_1]

The highest tariff wall imaginable won’t guarantee a return of manufacturing to the U.S. — not, at least, until industry addresses the structural barriers that keep the country from competing with China and other sources of cheaper production.

Chief among those obstacles is people. American manufacturers face a triple deficit of numbers, skills and labor cost. To close the gap with foreign competition, they’ll need to embrace two aspects of modern-day technology: artificial intelligence and 3D printing.

AI is being touted today as the solution to any number of business challenges, making it tough to separate substance from hype. But when it comes to manufacturing, the technology holds substantial promise for multiple stages of production, according to at least one industry expert.

Nikhil Gupta is a senior member of the Institute of Electrical and Electronics Engineers (IEEE), as well as a professor of mechanical and aerospace in the Engineering Department of New York University. He sees AI as playing a key role in four distinct areas: design, printing, testing and new material development.

Start at the beginning. “You can automate the entire process of design,” he says — at least in the sense of creating multiple options. “You take a general shape, apply constraints, then it runs iterations and comes up with many solutions.”

At that point, a human steps up to make the final design choice, but automation has already done much of the grunt work that otherwise ratchets up cost and prolongs the development cycle.

Gupta says AI can be of particular benefit at the design stage in medical devices and aerospace, “but once you have design software, you’re going to be using it to manufacture pretty much anything.”

Crucial to the product-design phase, of course, is selecting the right materials. AI can account for factors such as corrosion, electrical conductivity and environmental impact. Traditionally, says Gupta, that’s been a lengthy process requiring extensive testing and experimentation. Again, AI can consider a lot more relevant data than even an experienced team of humans can handle — especially in a time of tighter regulation, growing environmental awareness and reassessing of sourcing strategies.

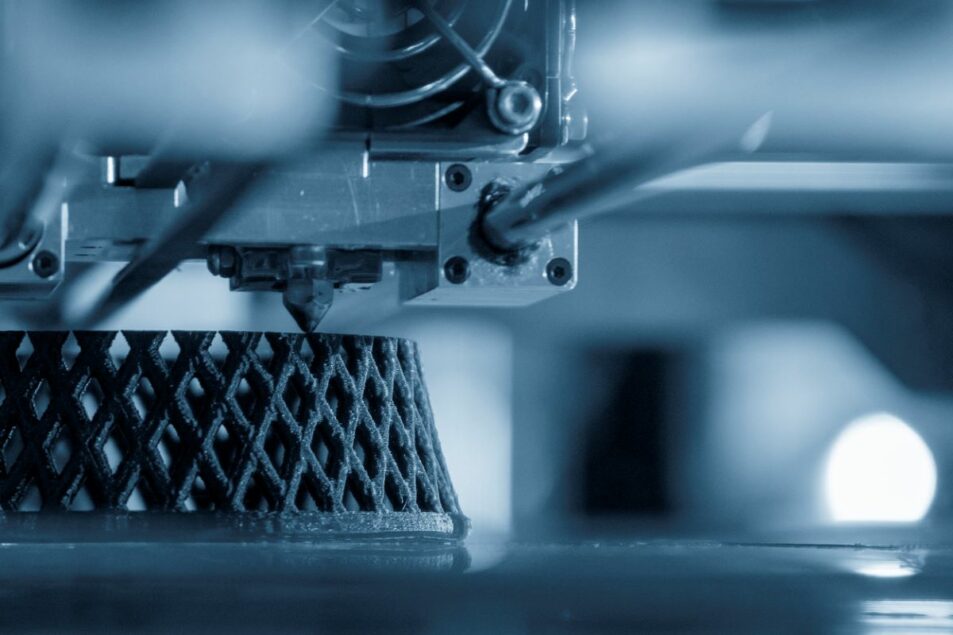

3D printing, or additive manufacturing, has been floating around in the industrial space for a number of years. “The technology is quite mature,” Gupta says, citing, once again, aerospace and medical as major adopters. Automotive is using it, too, although “it’s a much more price-conscious sector.”

3D printing presents the ability to do more localized production of components. Gupta says it’s a valuable tool for speeding up time to market, especially in the form of manufacturing as a service, or MaaS. “You can send your file by email, then they make and send the part back to you,” he says. That can be of particular value in the consumer products arena, where buyers harbor high expectations of response time.

3D printing probably isn’t suited to large runs. “If you’re averaging 10,000 pieces, you’re probably not going to go to it,” Gupta says. “But after you’ve sold a product and need 10 replacement parts, it becomes more useful.” The technology is also ideal for serving a customer base that demands multiple design variations, which can be outputted only as they’re needed.

Neither AI nor 3D printing eliminates the need for a multi-tier supply chain, which is essential to just about every production environment. But the technology can reduce the number of skilled humans needed to work the machines and churn out product, and the possibility of bringing design physically closer to final production makes domestic manufacturing more feasible.

As for the question of adoption, both types of technology are far from being completely integrated into most manufacturing environments. Gupta is nevertheless bullish on their potential for streamlining the production process and motivating companies to consider reshoring. “You spend so much time, energy and money developing composite-material tool parts,” he says. “AI can replicate them easily.”

[ad_2]

Source link