This week the aviation world will be literally flooded with press releases, product news and announcements about new aircraft or engine orders from the Paris Airshow. Getting your message heard above that din is not easy, so engine maker CFM International has jumped out of the box early.

LEAP engines under the microscope

Yesterday CFM International, the 50/50 joint venture between GE Aerospace and Safran Aircraft Engines, updated the progress of its new-technology RISE engine program and also spoke about the performance of its LEAP narrowbody engine. The LEAP is the exclusive powerplant for the Boeing 737 MAX and competes with Pratt & Whitney on the Airbus A320neo family.

Photo: Aeromexico

According to a Reuters report yesterday, CFM International (CFM) said it is redesigning some parts on the LEAP engine to address durability and time on wing issues. While most of the news around these concerns has focussed on the Pratt & Whitney GTF (geared turbofan) engine, the LEAP is also not delivering the time on wing between maintenance visits that CFM, nor its customers, expect.

For both OEMs, the issue is more pronounced in harsher environments, like India and the Middle East, although it has also risen with operators in kinder environments, such as airBaltic, Spirit Airlines and Air New Zealand. The extreme operating temperature of the engine’s hot section is at the heart of Pratt & Whitney’s problems, while the LEAP is dealing with issues on high-pressure turbine blades and turbine nozzles.

In a briefing ahead of the airshow, CFM said measures to improve durability in hot and dusty climates would also extend the time on wing in normal ones, which is good for operators outside of India and the Middle East. The Reuters report said CFM engine utilization had returned to 92% of pre-pandemic levels, while production of new LEAP engines would increase by 50% this year to 1,700 engines.

The RISE program two years on

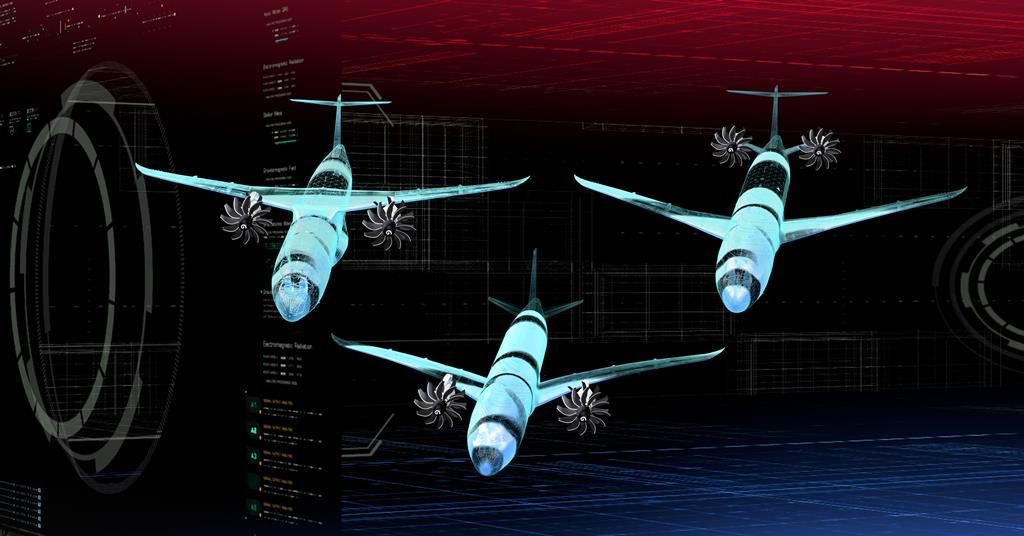

CFM released an update on its Revolutionary Innovation for Sustainable Engines (RISE) yesterday which said it had completed more than 100 tests on the program. CFM is taking a very wide-ranging approach to what engines of the future will look like and is advancing a suite of pioneering technologies, including the Open Fan approach.

Photo: CFM International

Other technologies being evaluated by CFM include thermal management, compact core, advanced combustion technology, and hybrid electric systems to be compatible with 100% sustainable aviation fuel. New technologies are also being matured to test direct hydrogen combustions.

Testing has so far validated the novel open fan architecture with its greater propulsive efficiency and lower noise output. The RISE program targets 20% better fuel efficiency with 20% lower CO2 emissions compared to the most efficient engines in service today. That’s a 20% gain over the P&W GTF and the CFM LEAP and an amazing progression from older-generation engines still in use. President and CEO of CFM International Gaël Méheust said:

“The RISE program was launched as the absolute manifestation of our deep commitment to push the boundaries of innovation and deliver the breakthrough technologies that will help achieve our most aggressive sustainability goals in support of the industry promise of net zero by 2050.”

CFM is on track to do ground and flight tests in the middle of this decade, and parent company GE Aerospace believes that the open fan architecture could unlock the single greatest jump in generational efficiency that CFM has ever achieved. Between them GE Aerospace and Safran Aircraft Engines have more than 1,000 engineers globally supporting development of RISE program technologies.

Sources: Reuters, CFM International