By Heico Sandee, founder and CEO of Smart Robotics

Robotics and automation undoubtedly address several safety and efficiency challenges that warehouses have grappled with for years.

While efficiency and productivity are primary motivations behind automation, warehouses must prioritize the safety and well-being of those who spend most of their time around these automated systems – the employees.

Productivity and profitability mean little if warehouses are unsafe. Numbers speak for themselves as the National Safety Council reports that a worker injury costs companies an average of $38,000 in direct expenses, while indirect costs can amount up to a total of around $150,000 per accident.

Automation planning, therefore, should be centered around employee safety, striking the balance between productivity and workforce morale.

Automation can make warehouses safer for employees in contrast to traditional systems

Previously existing gaps in safety measures are being bridged by new innovations like collision-avoidance sensors, that not only handle heavy lifting but also anticipate worker movement, ensuring a safer interaction on the warehouse floor.

By taking over hazardous tasks, automation reduces the risk of injuries related to lifting, manual handling and mitigates common warehouse hazards such as slips, trips, and falls.

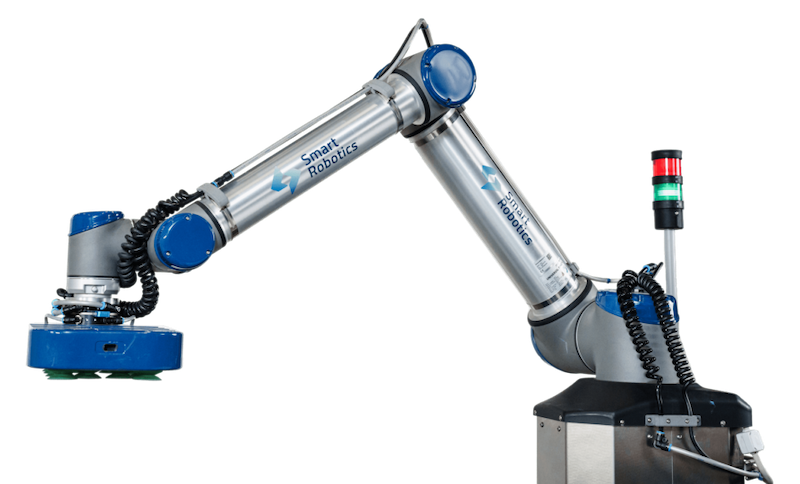

As a case in point, Smart Robotics’ intelligent cobot solution Smart Palletizer was implemented by an Australian milk formula manufacturer seeking to improve employee safety – a project that later received a nomination for a Safety Award for its positive impact on workplace safety.

Their previous manual stacking process involved two staff members, leading to health issues such as repetitive strain injuries and blind spots for forklifts, increasing accident risks.

The Smart Palletizer, with its compact design and easy integration into the existing processing and packaging line, allowed the manufacturer to reduce labor requirements by 50 percent, cutting costs while eliminating the safety hazards associated with manual palletizing.

Ensuring proper implementation to prevent mishaps and accidents

Thorough warehouse planning and robust safety protocols must be put in place to make sure that new systems do not inadvertently introduce new risks.

For instance, if automated systems are not properly integrated or lack adequate safety protocols, they can heighten the risk of collisions between machines and employees, leading to potential accidents or equipment malfunctions.

After all, the solution to one problem shouldn’t become another problem.

Providing warehouse employees with sufficient training to rightly interact with automated systems is a crucial step toward maintaining a safe workplace. It’s essential that there are no instances of confusion, incorrect use or unsafe interactions in the day-to-day operations.

Pedestrian safety, for instance, shouldn’t be overlooked. Warehouse staff moving between work areas, managers or supervisors conducting inspections, maintenance workers or even delivery or logistics personnel who may need to move through the warehouse on foot, all share space with forklifts, automated guided vehicles (AGVs) and other machinery, exposing them to risks of accidents.

This means that irrespective of an employee’s role or how closely they work with automated systems, everyone should receive basic training on essential protocols and safe practices on the warehouse floor.

Similarly, all employees should be familiarized with emergency procedures in the event of a system malfunction and better yet, regular maintenance and updates must not be missed to prevent such incidents in the first place.

Prioritizing mental health

Automation relieves employees of numerous repetitive and physically demanding tasks, however, such changes can also potentially introduce new stressors, including fears of job displacement, pressure to match machine efficiency, and the urgency to adapt to a highly automated environment. Therefore, change management should be considered a high-priority area.

Encouraging clear communication is one of the most fundamental tenets to be practiced to create a balanced, positive work environment. The importance of clearing the air of anxiety and addressing any concerns cannot be emphasized enough.

Regularly providing updates about changes, prompting feedback and suggestions, and creating forums for open dialogue are some of the ways in which organizations can ensure that implementations do feel enforced or one-sided.

Mental health check-ins at regular intervals, along with helpful resources such as counseling and stress management workshops, are essential during the transition phase and beyond.

These initiatives help employees navigate changes, address ensuing challenges, and promote their overall well-being. These also present opportunities for businesses to reevaluate their mental health support systems and to make warehouses less stressful places to work.

Moreover, investing time and resources in retraining and upskilling programs helps employees perceive automation as a catalyst for career advancement rather than as a threat. This contributes to greater job security and job satisfaction.

Adapting to changes is hard enough; employees shouldn’t have to stress about handling complicated systems. Automation should be designed and implemented in a user-friendly and intuitive manner, such as collaborative robots (cobots) that can work safely alongside humans.

Today, technologies are designed to directly improve safety through AI-powered sensors, predictive maintenance, and machine learning systems that proactively predict and avoid hazardous situations.

Planning for ergonomics

Workplace ergonomics has lasting implications for employees – especially so in activity-intense settings like warehouses.

Given that traditional warehousing involves substantial heavy lifting, prolonged periods of standing or walking, and repetitive movements throughout the day, it is important to understand the ergonomic challenges currently faced by employees while planning for automation.

Proposed changes must not only ensure that automated systems effectively address these issues, but they must also anticipate potential strains from new systems and work to prevent them.

For example, implementing adjustable robotic workstations and selecting cobot models designed for repetitive yet safe movements can significantly alleviate ergonomic challenges.

At its core, automation can lower the risk of hazards such as repetitive strain injuries (RSI) and discomfort resulting from repetitive body movements.

When workstations and workflows are designed consciously to fit the physical capabilities of employees, considering both their strengths and weaknesses, workers are less fatigued and can perform tasks more quickly and efficiently.

In this win-win situation, employees feel comfortable and safe in their workplaces, while organizations benefit from reduced absenteeism and a more engaged workforce.

Employee well-being

Decision makers in executive positions may not have first-hand experiences to foresee and gauge the potential impact of planned changes.

Particularly for warehouses that go from absolutely no automation to a significantly higher level of automation, it’s beneficial to include employees right in the earlier stages of automation.

Firstly, this will help identify and acknowledge employee pain points, fears and expectations regarding automation. Secondly, when employees feel involved in the process from the get-go, they are less likely to feel threatened and more inclined to embrace the collaboration.

As the primary users of automated systems on the floor, their input should be highly valued as a critical source for refining and improving these systems.

Involving employees in the easy adoption stages enables smoother transitions, eases the learning curve, and helps build a more resilient workforce.

Regular check-ins with operators regarding the user-friendliness of robotic systems and potential improvements can provide valuable insights, contributing to sustained operational excellence.

Together with upskilling opportunities, this approach prepares employees to confidently work alongside automated systems while instilling a sense of ownership and accountability over their roles in shaping a safer, more efficient workplace.

About Heico Sandee: Heico Sandee is founder and CEO of Smart Robotics, holds a PhD degree and previously acted as program manager for robotics at Eindhoven University of Technology. With more than 15 years of experience in robotics development, Heico now leads Smart Robotics in developing “intelligent, robot-independent software for flexible deployment of automated solutions”.

[ad_2]

Source link