Seth Catalli is an Enterprise Sales Leader at UiPath.

Editor’s note: this is the third article in a three-part series. Start the series by reading Benefits of an Automation Operating Model (Part 1).

Before I dive into the last article in this series, I want to invite you to join an executive discussion on automation operating models and strategies for accelerating your automation journey. We’ll jump into the discussion live on September 10, 2020 at 1:00 pm EST.

In part three of this series (this article), we turn to the key tipping point where automation crosses a threshold and spreads rapidly to touch every employee. The tipping point is automation at scale but personalized to the individual.

Reaching scale means the automation center of excellence (CoE) is building automations that:

- Span multiple departments

- Span enterprise applications

- Employ multiple technologies such as artificial intelligence (AI) and chatbots

But the real breakthrough is empowering every employee to use, create, and benefit from automation.

UiPath envisions enabling every customer to deliver ‘a robot for every person‘ in their organization. A robot for every person allows all employees to work smarter by using software robots to assist with their everyday tasks.

To reach the full potential of automation, organizations need three dimensions working in tandem:

- 1. Leadership creating automation targets to drive execution

- 2. A CoE capable of creating complex automations that drive massive value

- 3. Software robots on every desktop as digital assistants that drive mass adoption

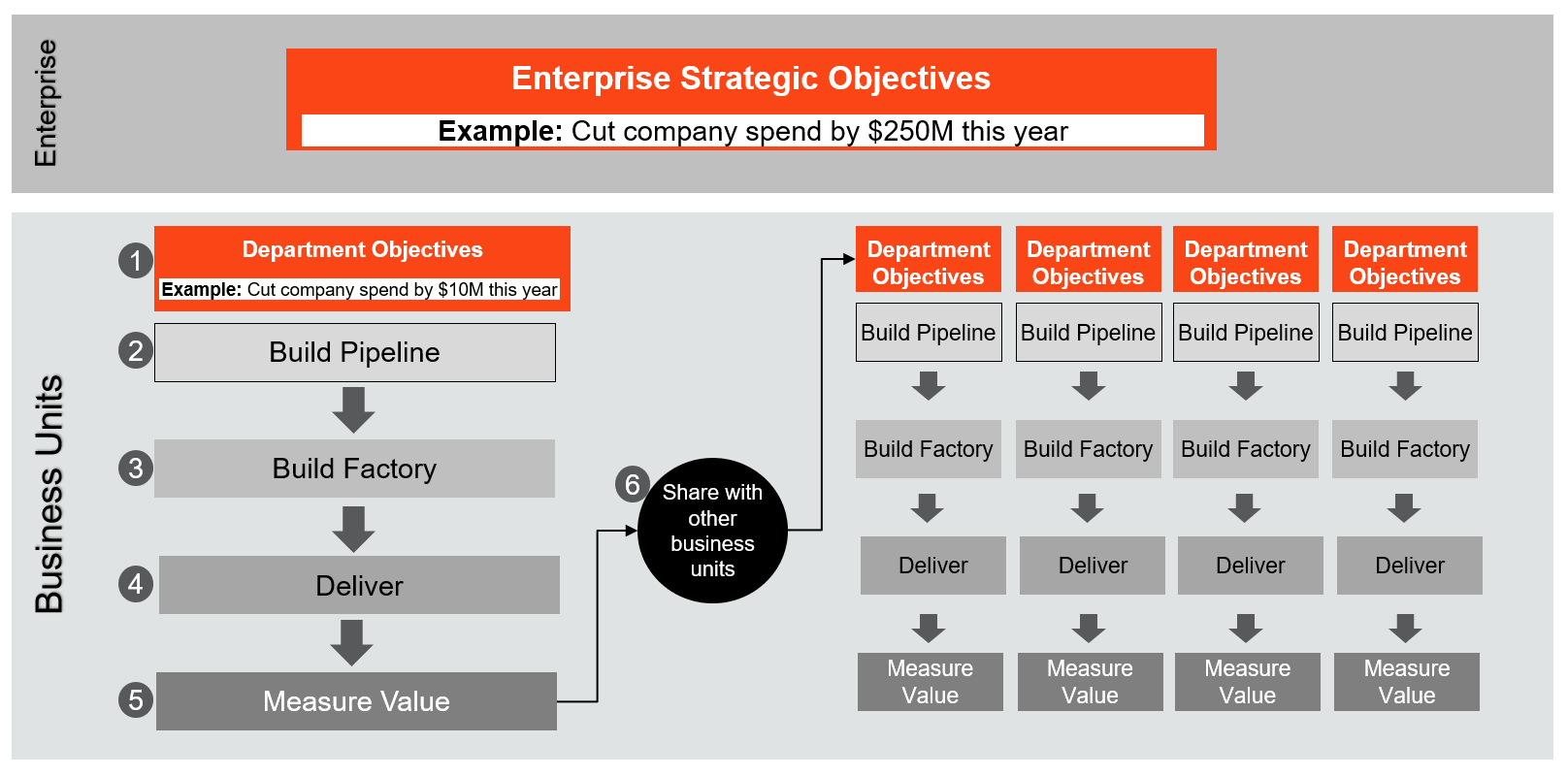

The automation operating model is a structured plan to execute on each of those simultaneously. It creates alignment between leadership, CoE, and business units across the six program elements shown in the figure below.

Source: UiPath

Without an automation operating model, the program can dissolve into a confusing list of projects.The tactical, project-based approach to automation inevitably drives to “low-hanging fruit” use cases. That is one of the common traps that prevents Robotic Process Automation (RPA) from scaling. What I have witnessed most often in these situations is that the automation program is almost solely dependent upon a mid-level manager’s preference instead of being tied to broader company goals.

Program targets and execution plan

When I ask customers that are running automations at scale to share what made them successful, a common pattern emerges:

- 1. First, they started with executive visioning and planning

- 2. Next, each business unit leader aligned by committing to business outcomes

- 3. Finally, employees within each business unit created ideas to fulfill annual goals

For example, I recently took part in a conversation with the chief financial officer (CFO) at a UiPath customer organization where he inspired his team to adopt automation based on a compelling vision of the future. His vision was one that everyone could instantly understand. He asked for a few minutes to kick off an employee meeting about automation. In less than 15 minutes, the executive communicated how automation will impact the company’s:

- Financial performance

- Competitive position

- Employee upskilling

He also explained how automation will help them align with technology trends to enhance customer experience over the next five years.

After the meeting, I complemented the CFO on his opening. While appreciative, he was quick to point out that aligning the team on using automation requires more than a vision.

He reminded me that companies with great visions are often beaten by competitors in the fast-paced business landscape of today. He stressed that operationalizing the vision means creating concrete financial targets per business unit using external benchmarks of automation potential.

The CFO said that after establishing annual automation goals by business unit, he expects each business unit leader to break them down by department or functional area. They should use the annual budget cycle to plan for the resources needed to meet these targets.

Let’s consider a fictional example. In our example, the enterprise-level objective is to cut $250 million in operating expenses within a year. Each business unit is required to contribute to that goal and that requirement cascades to the departments within each business unit. In the example shown in the diagram below, the first department will have a $10 million target to contribute to the operating expenses savings (see step one in the diagram).

Click on the image above to view a larger version of the image.

Employees of that department could submit automation ideas via UiPath Automation Hub to meet the departmental objective. UiPath Automation Hub facilitates the gathering and management of an organization’s automation pipeline (highlighted by step two in the diagram). This is important for change management: if employees do not have a say in creating the future, they often do not wholeheartedly buy in to the future vision.

Now here is the secret sauce: the CoE builds a “delivery factory” within each department. The delivery factory (shown in step three of the diagram above) can scale up or down based on the organization’s objectives. The delivery factory can also factor in the organization’s urgency to hit the targeted business outcomes. The factory can be staffed using:

- CoE resources as a shared service to the business unit

- Outside consultants hired on demand

- Full time developers hired directly within the business unit

- Citizen developers that build automations for their team (in addition to their day job)

I call it a factory because that is where the value is produced, which helps drive the departmental business outcome. For the purposes of our example, let’s say the delivery factory helps to deliver $10 million in savings for the year. By delivering and supporting automation primarily from within the business unit (see step four in the diagram), the business unit can control their own destiny and move at their own pace with governance provided by the CoE.

Value measurement

Financial targets have been set for each business unit by leadership. Check.

The analytics reading data from the software bots are automatically flowing into executive dashboards to show progress on achieving the targets. Check.

Employees within each department are delivering value using automation to meet the departmental objective. Check.

In step five of the diagram above a standard set of operational and financial metrics are used to measure automation value realized. When leaders choose the standard metrics, they must decide if the ‘hard cost savings’ really tells the whole story. In our example, reducing operating expenses by $250 million is the hard cost savings.

Executives appreciate hard cost savings because they are immediately quantifiable. However, they also understand that the most substantial part of the value is often harder to quantify (such as cost avoidance, employee loyalty, and risk reduction). Unlocking that value and quantifying it is what elevates the automation program to a key pillar of digital transformation.

I have seen executives present automation value measurement as:

- Cost avoidance: When a company grows revenue with a fully-scaled automation capability, the headcount growth can be expanded at a slower rate.

- Employee loyalty: When employees shed their repetitive, rule-based work using RPA, they free up their time for more meaningful work. Software robots are like any other morale-boosting activity such as employee wellness programs or free childcare. All of which are known to reduce the cost of employee turnover and recruiting.

- Risk reduction: RPA allows auditors to operate at a much higher level and improves audit quality. Automating tasks that do not require auditor judgement improves audit quality because it allows the auditor to focus on exceptions to reduce risks. Software bots record log data for every action they take in a business process so auditors love the transparency.

The above “soft-cost” savings do not include other value drivers such as positive impacts on revenue and customer experience that can often be primary drivers for automation. From my experience, executives will want to quantify these soft cost improvements and revenue value drivers conservatively and communicate them side-by-side with the direct operating expense savings.

Additional business unit expansion

In step six of the diagram, the insights into value are used by the executive sponsor to share the automation successes with other departmental leaders. Typically, those departments will want to set up their own automation programs. When the CoE enables a new business unit, the automation operating model is the interaction model between the business unit and the CoE that serves as an agreement on how to operate and build their own delivery factory.

Rinse and repeat for each successive department or functional area. This creates that tipping point (that I talked about in the beginning of this article) where automation rapidly expands across the organization.

Organization structure

In my blog Empowering Every Employee To Be An Automation Hero, I introduced the idea that a massive shift in influence is about to occur. In that shift, employees closest to the business processes will be empowered to take progressively more of a central role in the automation program by:

- Submitting automation ideas

- Documenting the task or steps in a process

- Delivering operational efficiency by using automations daily with software robots on their desktop created by professional developers

- Creating simple task automation for themselves or others on their team (citizen developer)

In fact, some innovative customers have completely gamified this process with the CoE giving awards and recognition to non-technical contributors for top ideas and automations.

The organization structure changes with the maturity of the program from centralized to “federated.” This means that as employees within business units gain progressively more capability, the centralized CoE team changes their charter to support solution quality, governance, and controls rather than solely development.

For example, I have a customer that has a separate IT CoE and finance business unit CoE. They started off with a centralized CoE but over time changed the organization structure to a more federated model because the finance department became more mature and capable. The finance business unit saw the value in controlling their own destiny and prioritized funding to hire their own staff.

The CoE in IT is there to provide controls and compliance for finance but serves the other business units outside of finance that do not have the same level of staffing in a more hands-on way.

Solution quality

Not every automation idea that gets submitted to the CoE will be substantial enough to be prioritized for implementation. Any idea that has been submitted and not automated is an unsolved pain point.

By enabling the business units as described above, you can eliminate these pain points. However, in all cases, the CoE will be involved in quality control and assurance. The CoE is accountable for providing standards, templates, and methodologies to the rest of the organization.

Ensuring solution quality can be an area of friction between the CoE and the individual developers in the business units who are innovating to help drive business outcomes. A successful approach that I have seen is that the CoE engages through working with the HR or Learning Departments to deliver training as individual learning plans with specific certification levels.

CoEs will want to create a library of reusable components shared through UiPath Automation Hub. These provide standard ways to accomplish repeatable tasks such as logging into an application with proper security controls. Developers within the business units can start by consuming these reusable components certified by the CoE to build automations with a high degree of quality.

Governance and controls

While this approach to automation operating model gives great autonomy to each business unit, the CoE must provide a governance and control function. For example, a path to production for solutions will include phase gates to ensure code quality and compliance to all policies and standards.

Here are couple of examples of how the CoE controls help create an interaction model between departments to rapidly scale:

- Instant visibility of all automation projects to prevent duplicate work or working in silos

- Identifying the high value automations created by individual business units for sharing

- Quality checks of any citizen-developed automations that are meant for consumption by others

As this three-part series has demonstrated, the most ambitious companies pivot to turn the automation operating model into a genuine framework for digital business. While the broader opportunities for automation may be universal, the actual strategies and operational needs in one business unit, department, or region may be very different from another.

At scale, automation is no longer being driven solely by RPA professionals in the CoE. You’ve successfully reached scale when every employee can take advantage of these innovations with their own digital assistant. The digital assistant is an attended robot that serves as a mechanism for digital transformation on every desktop.

If you’re ready to make the automation operating model real in your organization, I recommend taking a week to jump start the program.

Start our three-day, instructor-led Automation Operating Model Foundations course. It will give you the tools to optimize your automation investment and a detailed understanding of descriptions and definitions of components, interactions, and core processes. The course is followed by a two-day jumpstart workshop to enable the attendees to use their new skills to apply to their organization’s unique needs in real time. And our Automation Consulting team provides assistance in the prescribed workshop environment.

[ad_2]

Source link