[ad_1]

The Challenge

Adidas experiences demand variations across the year for its state-of-the-art apparel. After acquiring Reebok, this became a more obvious challenge when trying to consolidate 70,000+ SKUs across DCs. In actuality, Adidas needed to combine the inventory of 5 different brands, without disrupting service to their retail stores and partners.

The Solution

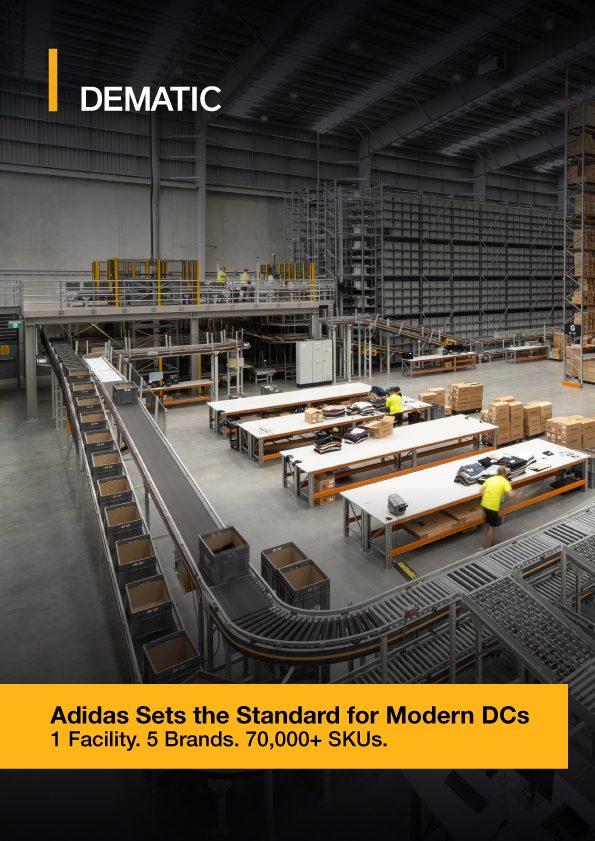

Adidas consolidated DCs into a 350,000 sq ft warehouse automated with Dematic ASRS, Goods-to-Person workstations, Put-to-Light, and Dematic Software.

The complete system has eliminated manual picking, boosted efficiency, and allowed the operations team to easily adapt to demand fluctuations – whether it is a new product launch, celebrity endorsement, or seasonal peak.

System Features:

- High-bay ASRS with pallet handling cranes

- Goods-to-Person picking system with high-rate put stations and put-to-light technology

- Real-time control via Dematic iQ software that integrates with their existing WMS

The Result

The investment in automation has delivered game-changing results for Adidas. The Dematic system allows the facility to process over 40,000 split-case items daily with peak pick rates reaching 1,500 units per hour.

Setting the Standard for Your Supply Chain

This success is setting the standard for the Adidas distribution strategy. Get their feedback and discover how you can apply similar strategies and advanced automation to your business.

[ad_2]

Source link